AD 2017-11-10 becomes effective August 15, 2017, though it will be replacing an AD that is already in effect.

The FAA is replacing AD-95-26-13, issued December 29, 1995, with a new airworthiness directive (AD 2017-14-04). AD-95-26-13 came about after numerous incidents/accidents that were caused by “rupture or failure of the oil cooler hose assemblies” in certain Piper Cherokee aircraft. It’s being replaced with the new AD in order to “clarify the intent of AD 95- 26-13,” and carry on the purpose of the previous AD, which was to prevent the rupture or failure of the oil cooler hose assemblies, which has the potential to result in “engine stoppage with consequent loss of control.”

More Details on FAA AD 2017-14-04

The AD applies to the following Piper Cherokee models, all serial numbers, certificated in any category, that are equipped with one or more oil cooler hose assemblies that do not meet technical standard order C53a (TSO-C53a) Type D requirements:

- PA-28-140

- PA-28-150

- PA-28-151

- PA-28-161

- PA-28-160

- PA-28-180

- PA-28-181

- PA-28-235

- PA-28-236

- PA-28R-180

- PA-28R-200

- PA-28R- 201

- PA-28S-160

- PA-28S-180

- PA-32-260

- PA-32-300

- PA-32-301

- PA-32-301T

- PA-32R-300

- PA- 32R-301 (SP)

- PA-32R-301 (HP)

- PA-32R-301T

- PA-32RT-300

- PA-32RT-300T

- PA-32S-300

Required Actions

For any oil cooler hose assemblies that do not meet TSO-C53a, Type D requirements, the FAA requires an initial inspection within 100 hours TIS from February 5, 1996 (the effective date of the previous AD), and then repetitive inspections “at intervals not to exceed 100 hours TIS.” The inspection focuses on the fire sleeve of each oil cooler hose assembly, looking for:

- Soaked oil

- A brownish or whitish color

- Any evidence of brittleness or deterioration as a result of heat or oil seepage.

The AD, which you can find a link for below in the ‘documents’ section, provides details on how to carry out the inspection procedures for oil cooler assemblies that are either:

- Mounted AT or AFT of the rear of the engine

- Mounted in a location other than AT or AFT of the rear of the engine

In addition, though it is not required by the AD, the FAA recommends that an oil cooler hose assembly flexibility test be done at the 100 hour TIS inspection intervals as well “by gently lifting each oil cooler hose assembly in several places along its bottom surface, ideally at the center of an arc. If the oil cooler hose assembly moves slightly, either from side-to-side or upward, then some flexibility remains. If the oil cooler hose assembly appears hardened or inflexible, replacement is recommended.”

If after the required inspections are carried out, it is necessary to replace an oil cooler hose assembly, you have two choices:

- Replace the oil cooler hose assembly with a serviceable new or used TSO-C53a Type D oil cooler hose assembly

- Replace the oil cooler hose assembly with a serviceable new or used TSO-C53a Type C oil cooler hose assembly. A used TSO-C53a Type C oil cooler hose assembly must have documented hours TIS.

If you decide on installing a new or used TSO-C53a Type C oil cooler hose assemblies, you will need to continue the inspections in accordance with the AD. In addition, the FAA notes that Type C assemblies must also be replaced when they accumulate “8 years or 1,000 hours TIS, whichever occurs first.”

However, if you go with Type D assemblies, resulting in “both oil cooler hose assemblies of an airplane meeting TSO-C53a Type D requirements, then the requirements of this AD are terminated for the airplane.”

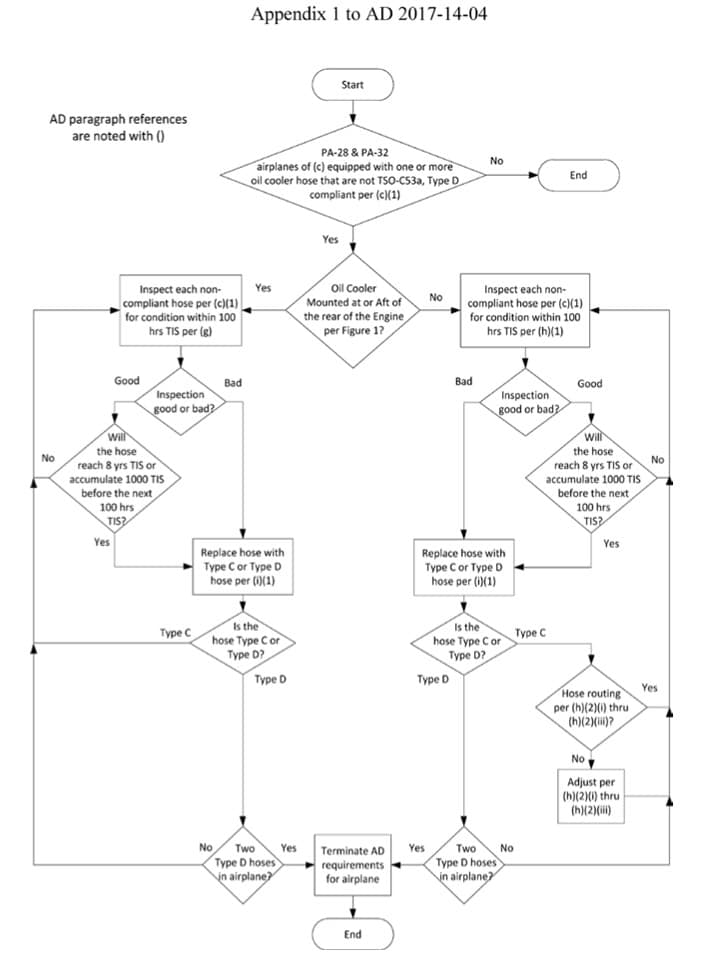

As a nice touch, the FAA also provided a graphical flowchart to outline the steps of the AD.

Cost Associated with Compliance

The FAA estimates that the AS affects 23,643 airplanes on the US registry, and also estimate the following costs for complying with the AD:

| Action | Labor cost | Parts cost | Cost per product |

| Inspection of the oil cooler hose assembly | 1 work-hour × $85 per hour = $85 | n/a | $85.00 |

| Inspection of the clearance between the oil cooler hose assembly and the front exhaust stacks | .5 work-hour × $85 per hour = $42.50 | n/a | $42.50 |

| Replacement of the oil cooler hose assembly | 1 work-hour × $85 per hour = $85 | $430.00 | $515.00 |

The agency does note that “The estimated cost of the inspection of the clearance between the oil cooler hose assembly and the front exhaust stacks is for all airplanes affected by this AD; however, the inspection applies only to airplanes with the oil cooler mounted in a location other than at or aft of the rear of the engine. We have no way of knowing how many affected airplanes have that particular installation.”

They also estimate the following costs for any necessary adjustments that would be required based on the results of the clearance inspection, again noting that they have no way of determining how many aircraft might need these adjustments:

| Action | Labor cost | Parts cost | Cost per product |

| Adjustment of the clearance between the oil cooler hose assembly and the front exhaust stacks | 1 work-hour × $85 per hour = $85 | n/a | $85.00 |

Documents

For a copy of FAA AD 2017-14-04, click here.

Contact Information

For more information about this AD, please contact FAA Aerospace Engineer Gary Wechsler:

- Address: Atlanta Aircraft Certification Office, 1701 Columbia Avenue, College Park, Georgia 30337

- Phone: (404) 474-5575 / Fax: (404) 474-5606

- Email: gary.wechsler@faa.gov

Rescuing an Indian: Restoring the Piper Cherokee

Rescuing an Indian: Restoring the Piper Cherokee

A few weeks ago a new client came to the shop. He was looking for some advice and help in purchasing an airplane. He currently owned a Piper Cherokee 140 that he had purchased a few years ago and had learned to fly in. When the annual was due earlier this year he took it into a local repair station and it was found not airworthy for a number of reasons. The estimate for the shop to get the airplane signed off was over $10,000. [Read More]

Leave a Reply